Smcon Lab is a manufacturer of Magnetic Stirrer with Heating, Multi-point Magnetic Stirrer with Heating, today we would like to introduce the principle of magnetic stirring.

Magnetic Stirrer adopts magnetic coupling mechanism to make the stirring shaft rotate synchronously in the closed pressurized cavity (also known as isolation sleeve), which solves the long-standing problem of shaft leakage of chemical stirring reactor, and can make the flammable, explosive and toxic chemical reaction process realize leakage-free operation on high temperature, high pressure and high Rotation Speed stirring condition.

Magnetic drive (or magnetic stirring) technology can make the dynamic sealing into static sealing, is the use of magnetic super-torque effect characteristics and realize. The dynamic seal that transmits torque from the spindle can be transformed into a static seal, realizing zero-leakage transmission of power.

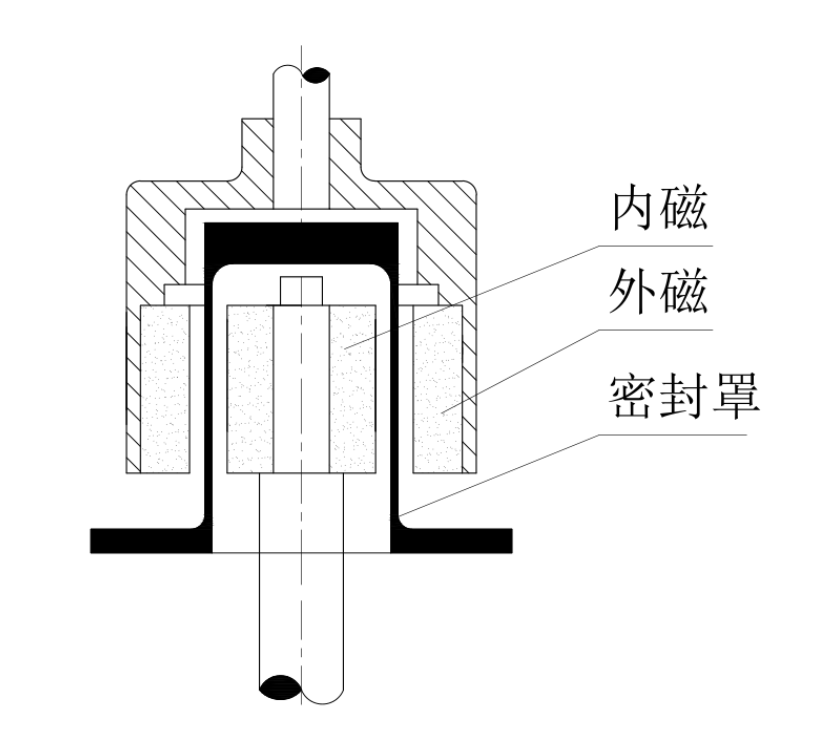

In the magnetic drive reactor series generally choose the cylinder type magnetic drive more. (Cylinder type attached)

Rare-earth permanent magnet material is selected, and its high magnetic energy product and high coercivity are utilized to arrange the magnets of different polarities densely together. The disk type magnetic actuator is composed of internal and external magnets. When there is no external force, the different polarity of the external and internal magnets are suctioned together with each other, the external magnet is driven by the motor (external force), and the displacement is generated under the external force, due to the inertia and the role of the load to make the external magnet and the internal and external magnetic poles of the external magnet are dislocated, and at this time, the poles of the internal and external magnets, in addition to the attraction of the opposites of the mutual attraction of the poles, there is also a repulsive force of the same poles of the mutual repulsive effect. The suction and repulsion form a "push-pull" force, which drives the displacement of the internal magnet and realizes the magnetic transmission.

The isolation sleeves are made of non-conductive materials. They do not affect the suction and repulsion between the internal and external magnets, i.e. they do not affect the transmission of torque.